Chicken Nugget Freezing Processing Solution

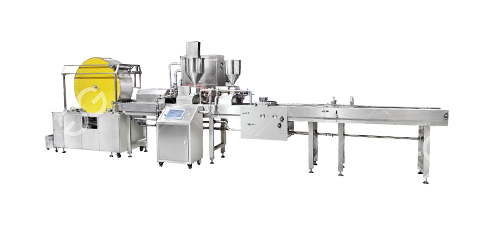

Provide complete chicken nugget solutions including meat processing, battering machines, breading machines, forming, freezing, packaging and other equipment. The use of advanced food processing technology can ensure product quality and safety.

| Machine | Parameter |

| Chicken Nuggets Forming Machine | Model:GG-400 Power:11.2kw Belt speed:3-15m/min Input/Output height:1050+/-50mm Size:2830*850*2140mm |

| Chicken Nuggets Paste Starching Machine | Model:GG-400 and GG-200 Power:2.95kw Belt speed:3-15m/min Input/Output height:1050+/-50mm Size:2660*890*2285mm |

| Chicken Nuggets Breading Machine | Model:GG-400 Power:2.6kw Belt speed:3-15m/min Input/Output height:1050+/-50mm Size:1800*850*1490mm |

| Chicken Nuggets Frying Machine | Model:GG-6000 Capacity(based on materials):500kg/h Power:100kw Dimension:3500*1200*2400mm Weight: 800kg |

| Vibrate Oil Removing Machine | Dimension: 1800*1000*900mm Power: 0.5KW/380V/50Hz |

| Cooling Conveyor | Model:GG-5 Capacity :800-1000kg/h Power:1.1+4*0.75kw Voltage:380V,50HZ Weight:450kg Size:5000*1200*1400mm |

- Cutting Machine

- Butter Mixer Machine

- Powdering Machine

- Starching Machine

Wide Range of Applications

The multi-functional chicken nugget freezing solution accommodates diverse raw materials, offers a wide array of products, and supports varied shapes. Its versatility extends to processing various chicken-based ingredients, enabling the production of a rich assortment of nugget types in different shapes and sizes.

Precision Manufacturing of Equipment

The entire solution uses pneumatic transmission, mechanical transmission, and a high degree of automation. It can automatically complete filling, forming, output and other processes, and the production process is hygienic, safe and reliable.

High Quality Materials

The whole machine is made of high-quality 304 stainless steel and other food materials, which complies with hygienic standards and HACCP standards and is easy to clean and maintain.

Support Customization Requirements

Anything that can be machined can be customized, and the maximum diameter that can be processed is ≤140mm. It can be connected to flour (slurry) machines, frying machines and other equipment. Product replacement is quick and only requires the mold to be replaced.