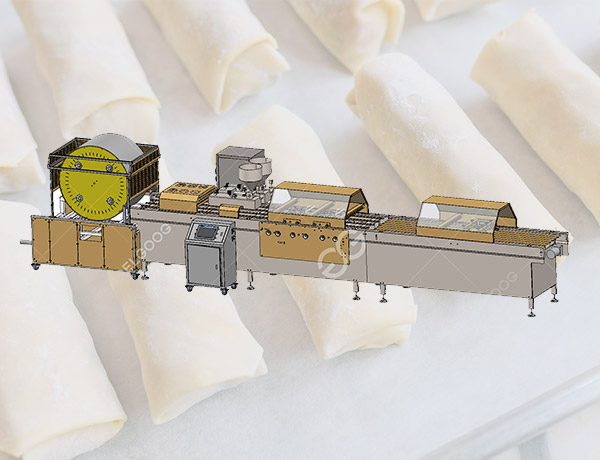

Spring Roll Freezing Processing Solution

This solution provides complete equipment, technology and services for the production of frozen spring rolls. It covers all technical aspects of frozen spring roll production, including wrapper making, stuffing processing, filling, forming, freezing, packaging, etc.

| GG-CJX5000 | |||

| Name | Dimensiton(mm) | Power(KW) | No. |

| Spring Roll Wapper Part | 2200*2000*2200 | 59 | 1 |

| Stuffing Part | 700*600*1000 | 0.4 | 1 |

| Spring Roll Folding Part | 1700*500*1360 | 0.4 | 1 |

| Spring Roll Forming Part | 4030*500*1100 | 0.4 | 1 |

| Batter Mixer | 1300*600*900 | 1.1 | 1 |

| Batter Tank | 800*300*320 | / | 1 |

| Batter Pump | - | 0.55 | 2 |

| Capacity 3000-4000pcs/h | |||

- Baking Host

- Filling Machine

- Folding Machine

- Rolling Machine

- Freezer Machine

- Packaging Machine

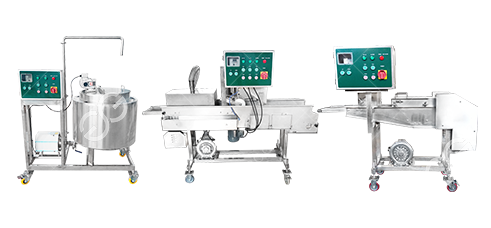

Mixer Machine

This mixer machine can mix the ingredients evenly and makes the batter smooth. Adjustable speed settings ensure precise mixing. The machine's robust design facilitates easy cleaning and maintenance.

Spring Roll Wrapper Machine

The spring roll wrapper machine is a piece of equipment specially used to make spring roll wrappers. The machine can efficiently bake the batter into thin and even spring roll skins, ensuring a uniform texture.

IQF Freezer Machine

The freezer machine is a device specially designed for spring roll production and is designed to quickly freeze spring rolls to maintain their freshness and quality. This kind of machine usually uses rapid freezing technology, which can quickly freeze the spring rolls to the required temperature, preventing freezing or quality degradation during the freezing process.

Packaging Machine

The packaging machine can automatically complete the packaging and sealing of spring rolls, usually using food-grade packaging materials to ensure the freshness and hygiene of the spring rolls. This machine is easy to operate and can adjust the packaging size and form as needed to accommodate spring rolls of different specifications.

Advanced Temperature Control System

Using an advanced temperature control system, baking is more precise and the color of both sides of the spring rolls is even. Using electromagnetic heating, the thermal efficiency is higher, the maintenance cost of the equipment is lower, and the safety performance is higher.

Good Molding Fffect for Finished Product

Using the one-time molding principle, the spring roll skins produced are uniform in size and thickness. It can wrap different fillings and make spring rolls of the same size, ensuring the quality of the finished spring rolls.

Full Operation Automation of the Equipment

The frozen spring roll solution has a high degree of automation in the entire line, and the equipment is easy to operate. The length and width of the spring rolls are adjustable, and the size can be customized according to the mold. It is suitable for the production of spring rolls of various specifications.

Equipment Materials Are Safe and Hygienic

All made of stainless steel, the production process of quick-frozen spring rolls is more hygienic and healthy. The equipment has a reasonable structure, is sturdy and durable, and is very simple and convenient for maintenance, disassembly and cleaning.