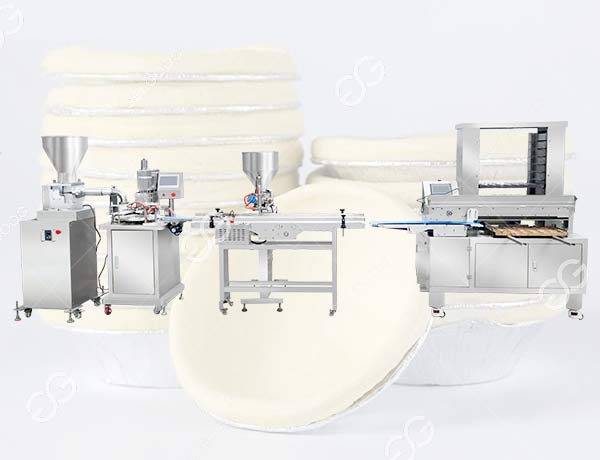

Egg Tart Shell Freezing Processing Solution

This solution includes the entire process of dough mixing, egg tart shell forming, arranging, freezing, and packaging. The use of automated production equipment can greatly improve production efficiency and shorten the production cycle.

| Model | GGA303-1 |

| Capacity | 1500-1800PCS/H |

| Voltage | 220V,50hz |

| Diameter of Tart | 40-90mm |

| Size | 840*800*1300mm |

| Weight | 130kg |

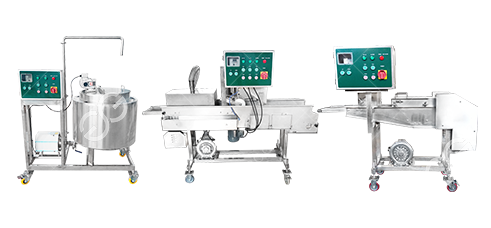

- Dough Mixing

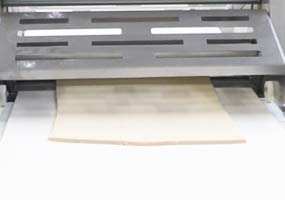

- Dough Pressing

- Tart Shell Forming

Dough Mixing Machine

The mixing machine is suitable for mixing the dough evenly. Its precision in mixing speeds and thorough incorporation of ingredients streamline the dough preparation process for various bakery products.

Egg Tart Shell Forming Machine

Egg tart shell forming machine is used to make high-quality egg tart crust. It can press the dough into uniform-sized egg tart shells for making egg tarts.

Tart Shell Freezing Machine

The tart shell freezing machine is a device specially used to quickly freeze egg tart shells. This machine uses advanced freezing technology to quickly freeze the tart shell to the required temperature.

Tart Shell Packing Machine

The tart shell packaging machine is a special equipment for egg tart shells. This machine has automated features that allow it to adjust packaging size and form according to needs.

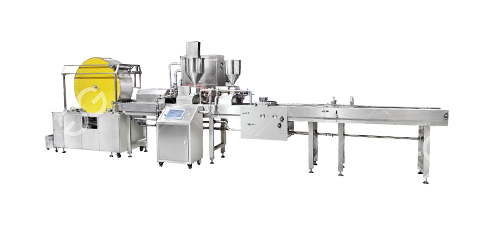

Operational Automation

It can be used with automatic feeding machine, egg tart machine, automatic cup filling, rapid forming + egg liquid feeding machine + automatic plate placing machine and other equipment for production line operation.

Wide Range of Applications

This equipment is controlled by PLC touch screen and can replace different molds to produce products of different shapes. Molds can also be customized according to your needs.

Parameters Adjustable

The egg tart crust is cut automatically without manual intervention, and the error range of each egg tart crust is controlled within 2 grams.

High Productivity

The entire solution is automated, with high production efficiency and large production capacity. And the equipment is easy to clean and maintain. Can save labor costs.