Industrial Egg Tart Shell Freezing Machine For Sale

- Capacity: 300KG/H

- Voltage: 380V

- Materials: Stainless Steel

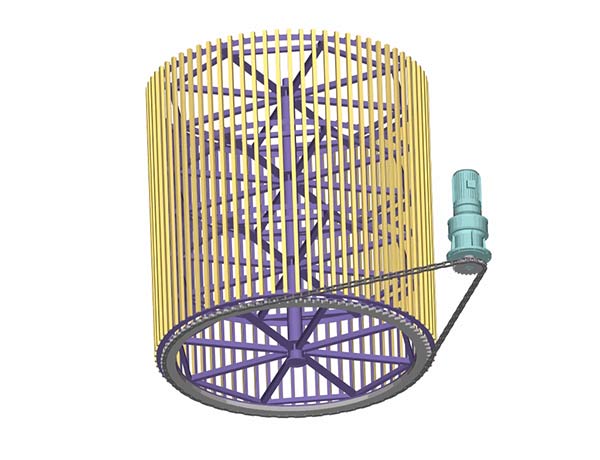

The egg tart shell freezing machine, also known as the spiral freezer. It is designed specifically to cater to the needs of bakeries and food processing units, offers a streamlined solution for freezing egg tart shells.

The machine can process large batches of egg tart shells, quickly freeze them to the required temperature, and then transport them to major supermarkets and factories.

Working Principle of Tart Shell Freezing Machine

The freezer operates on a simple yet effective principle. As the egg tart shells enter the machine, they are swiftly transported through a spiral conveyor system. This conveyor is enveloped by a freezing environment, ensuring rapid and uniform freezing of the egg tart shells. This machine not only maintains the quality of the tart shells but also enhances their shelf life, preserving their freshness and taste.

Advantages of Egg Tart Shell Freezer Machine

- Strong adaptability, it can handle a wide range of production capacities, accommodating bakeries and large-scale manufacturing units. Its customizable freezing speeds and temperature settings offer unparalleled control over the freezing process, allowing businesses to tailor the operation according to their specific requirements.

- This tart shell freezer machine adheres to stringent hygiene standards, featuring easy-to-clean surfaces and materials that meet food safety regulations. Its user-friendly interface ensures straightforward operation, reducing downtime and maximizing productivity.

- The egg tart shell freezing machine stands as a pinnacle of efficiency, reliability, and quality in the realm of food freezing technology. It revolutionizes the production process, enabling businesses to meet consumer demands for premium-quality egg tart shells consistently.

- Apart from its effective freezing capabilities, this freezing machine showcases sustainability elements. Through its energy-efficient design that minimizes power usage while optimizing freezing efficiency, it not only decreases operational expenses for businesses but also adheres to eco-friendly practices, fostering a more environmentally conscious and sustainable food production process.

Furthermore, the freezer machine's innovative design allows for easy integration into existing production lines. Its compact footprint and adaptable configurations enable seamless installation, optimizing space utilization within food processing facilities. This versatility empowers businesses to enhance their production capabilities without extensive redesign or space constraints.

The egg tart shell freezing machine, with its blend of efficiency, sustainability, and adaptability, represents a significant advancement in food freezing technology. Its ability to maintain the quality of egg tart shells while minimizing environmental impact positions it as a cornerstone for bakeries and food manufacturers striving for excellence in both product quality and responsible production practices.

| Discharge temperature | ﹣18℃ |

| Internal temperature | ﹣38℃ |

| Capacity | 300KG/H |

| Refrigeration energy consumption | 70KW |

| Freezing time | 12-60min Adjustable |

| Belt width | 2400MM |